Introduction to Fanuc PCB

Fanuc PCB, an integral component within the world of automation and manufacturing, primarily serves as the backbone of various electronic devices. It is essential for facilitating the seamless operation of robotics and various industrial machines, contributing to the efficacy and productivity that industries strive for today. Fanuc, a renowned leader in automation solutions, designs and produces a wide array of printed circuit boards (PCBs) tailored to meet the diverse needs of the market.

The significance of Fanuc PCBs lies in their ability to enhance the functionality of automated systems. From controlling complex machinery to ensuring precise handling and communication between components, these PCBs provide critical support in an assortment of applications. By employing advanced technologies, Fanuc guarantees that its PCBs are not only reliable but also capable of operating under the demanding conditions typically encountered in manufacturing environments.

Fanuc manufactures various types of PCBs, each designed for specific applications. These range from standard PCBs, commonly used in everyday electronic devices, to more specialized variants that cater to unique industrial requirements. For instance, some Fanuc PCBs are engineered to withstand extreme temperatures and vibrations, making them suitable for heavy machinery in industries such as automotive, aerospace, and semiconductor manufacturing. Other types may focus on high-speed communication functions, which are essential for maintaining synchronized operations in automated systems.

As technology continues to evolve, the role of Fanuc PCB within the manufacturing sector becomes increasingly significant. Companies rely on these specialized boards to ensure not only the efficiency of their processes but also to enhance the overall output quality. Understanding the critical aspects of Fanuc PCB is foundational for grasping its contribution to the progress and development of automation technology.

History and Evolution of Fanuc PCB

Fanuc Corporation, established in 1956, began as a supplier of numerical control (NC) systems in Japan. Its commitment to innovation quickly led it to become a pioneer in the automation and robotics industries. The company’s foray into printed circuit board (PCB) manufacturing began in the 1970s when the burgeoning demand for electronic components heralded a new era of technological advancement. Fanuc’s initial focus was on creating robust and efficient control systems, which helped lay the groundwork for its growth in the PCB sector.

Throughout the decades, Fanuc PCB has undergone significant transformations. In the 1980s, the incorporation of advanced robotics into PCB assembly processes marked a pivotal point in the company’s trajectory. These advancements not only enhanced production efficiency but also dramatically improved the precision of PCB manufacturing. As the technology progressed, so too did the complexity of PCB designs, leading Fanuc to develop innovative solutions to accommodate advanced manufacturing techniques.

By the 1990s, Fanuc had established a reputation as a leader in the PCB manufacturing industry, driven by strategic investments in research and development. The introduction of surface mount technology (SMT) and the shift towards automated assembly lines enabled Fanuc to produce high-density interconnect PCBs that are integral to modern electronic products. This evolution was crucial as the demand for smaller, faster, and more powerful devices surged globally.

Entering the 21st century, Fanuc continued to adapt to rapidly changing market dynamics. The company’s commitment to quality and sustainability became evident through its integration of eco-friendly manufacturing processes. Furthermore, the rise of Industry 4.0 influenced Fanuc’s PCB operations, incorporating IoT solutions that enhanced monitoring and data analytics capabilities. Today, Fanuc stands as a formidable entity in the PCB manufacturing landscape, constantly evolving to meet the needs of a diverse array of industries.

Features of Fanuc PCB

Fanuc PCBs, recognized for their superior performance, are ingrained with a multitude of distinctive features that make them stand out in the competitive landscape of printed circuit boards. One of the key attributes is their innovative design, which is meticulously engineered to enhance efficiency and functionality in various applications. The advanced layout of Fanuc PCBs facilitates optimal component placement, ensuring minimal signal interference and maximizing electrical performance.

Durability is another salient feature of Fanuc PCBs. These boards are constructed using high-quality materials that are resilient against environmental stressors such as temperature fluctuations, moisture, and mechanical wear. This robustness ensures that Fanuc PCBs maintain their integrity and performance even in harsh conditions, leading to a lower failure rate and extended lifespan. The longevity of these boards significantly reduces maintenance costs and enhances operational reliability for manufacturers and users alike.

Reliability is paramount in any electronic system, and Fanuc PCBs exemplify this through rigorous testing and quality control measures in their production process. Each board undergoes stringent quality assessments, ensuring that every unit meets international standards and performs consistently over time. This commitment to quality is complemented by the integration of cutting-edge technology in the manufacturing process. Utilization of automated production techniques and advanced material science ensures that each Fanuc PCB is crafted flawlessly, reflecting the company’s dedication to excellence.

Additionally, Fanuc PCBs incorporate features such as thermal management solutions and high-frequency performance capabilities, making them suitable for various applications ranging from industrial automation to robotics. The thoughtful design and engineering of these printed circuit boards underscore their role in delivering reliable and efficient performance, setting them apart from competitors in the market.

Applications of Fanuc PCB in Various Industries

Fanuc PCBs (Printed Circuit Boards) play a pivotal role in numerous industries, showcasing their versatility and significance. One of the most prominent sectors utilizing Fanuc PCBs is the automotive industry. These boards are integral to the development of electronic control systems in vehicles, which manage everything from engine performance to safety systems. For instance, in modern vehicles, Fanuc PCBs are utilized in advanced driver-assistance systems (ADAS) that enhance safety features, such as lane departure warnings and automatic braking, demonstrating the integration of sophisticated electronics in automotive applications.

Another sector where Fanuc PCBs find extensive usage is robotics. In this field, these boards support various robotic functionalities, enabling precise motion control, sensor integration, and data processing. For example, in manufacturing environments, robotics equipped with Fanuc PCBs can perform tasks with high efficiency and accuracy, facilitating automation in assembly lines. Furthermore, these circuit boards are essential in collaborative robots (cobots), which work alongside humans in shared spaces, ensuring safety and effectiveness in tasks such as packaging and materials handling.

Telecommunications is another industry that greatly benefits from the use of Fanuc PCBs. These boards are foundational in the operation of network infrastructure, including routers, switches, and communication devices. They ensure reliable transmission of data and connectivity across various platforms, fulfilling the growing demand for high-speed internet and mobile communication. As the infrastructure for 5G networks expands, the importance of robust and efficient Fanuc PCBs in delivering enhanced performance cannot be overlooked.

In summary, the applications of Fanuc PCBs across automotive, robotics, and telecommunications illustrate their integral role in modern technology. Their ability to support complex electronic systems highlights their significance in driving innovation and enhancing operational efficiency within these industries.

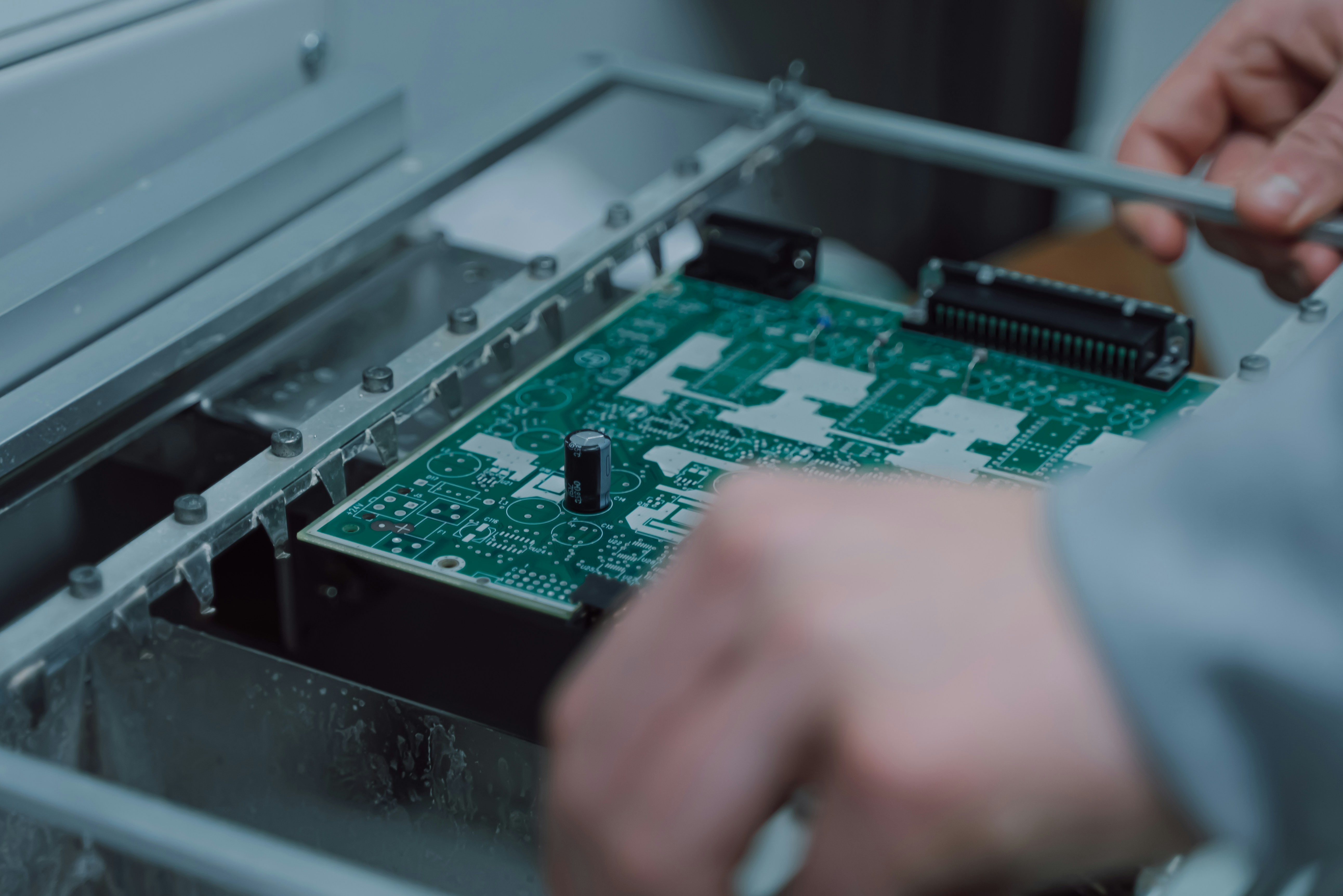

Manufacturing Process of Fanuc PCB

The manufacturing process of Fanuc printed circuit boards (PCBs) involves several intricate steps that ensure the highest quality standards suitable for various applications. Initially, the process begins with selecting appropriate materials, which commonly include fiberglass reinforced epoxy resin and copper foil. The choice of these materials is crucial as they provide the necessary durability and conductivity required in a modern PCB.

Subsequently, the materials go through a series of processes, including design and layout creation, typically executed via sophisticated software. Computer-aided design (CAD) tools allow engineers to develop precise designs that dictate the pathways for electrical connections. After achieving the design phase, the next significant step involves photolithography, where a photosensitive material is applied to the board. Ultraviolet light is then utilized to transfer the desired circuitry pattern onto the substrate, which is essential for defining connections.

Once the pattern has been established, the PCBs undergo an etching process. This involves removing excess copper to form the defined circuits, which allows for efficient electrical flow. Following etching, the boards are drilled to accommodate components such as resistors and capacitors, making way for thorough electrical connections. The application of a solder mask, typically green in color, is then applied to prevent unintentional solder bridging and to enhance protection against environmental factors.

Quality control measures play a vital role in the manufacturing of Fanuc PCBs. These measures may include automated optical inspection (AOI) to detect any defects in the soldering process or physical damage to the boards. Additionally, functional testing is conducted to ensure that each PCB meets the operational specifications set forth during the design phase. This rigorous quality assurance procedure is essential in maintaining the integrity and functionality of the final product.

Advantages of Using Fanuc PCB

Fanuc PCBs, or Printed Circuit Boards, have gained significant popularity in various industries due to their numerous advantages. One of the foremost benefits of using Fanuc PCBs is their exceptional performance. Engineered with precision, these PCBs are designed to support high-speed processing and robust signal integrity. This is particularly important in applications such as automation, robotics, and manufacturing, where timely and accurate performance is critical. The reliability of Fanuc PCBs ensures that even under rigorous conditions, the devices maintain optimal functionality, minimizing the risk of system failures.

Another advantage is the cost-effectiveness associated with Fanuc PCBs. Utilizing advanced manufacturing techniques and materials, these boards offer competitive pricing without compromising quality. This cost efficiency enables companies to optimize their production budgets while still improving operational capabilities. Additionally, the longevity of Fanuc PCBs contributes to overall cost savings in the long run. The durability and resilience of these circuit boards reduce the need for frequent replacements, thereby lowering maintenance costs and increasing return on investment.

Moreover, the long-term reliability of Fanuc PCBs plays a vital role in enhancing operational efficiency. By ensuring that equipment functions smoothly over extended periods, businesses can enhance their productivity while reducing downtime due to unexpected repairs. This aspect is particularly beneficial in high-demand environments where any interruption in operation can lead to significant financial losses. Furthermore, Fanuc PCBs are often engineered to support a wide range of temperatures and environmental conditions, making them suitable for diverse applications.

In summary, the advantages of using Fanuc PCBs, including superior performance, cost-effectiveness, and long-term reliability, significantly contribute to improving operational efficiency across various sectors. These benefits make Fanuc PCBs a preferred choice for organizations striving for enhanced productivity and sustainability in their electronic systems.

Challenges in Fanuc PCB Production

The production of Fanuc PCBs involves navigating a range of challenges that can significantly impact efficiency and output quality. One of the foremost issues is supply chain disruptions. The electronics industry is globally interconnected, and any inconsistencies in the supply of raw materials can lead to delays in production schedules. For Fanuc, which relies on specialized components, disruptions can cause considerable setbacks. Fluctuations in demand or geopolitical events can exacerbate these supply chain vulnerabilities, making it imperative for manufacturers to develop robust contingency plans.

Another critical challenge faced in the production of Fanuc PCBs pertains to technological constraints. The rapid advancement of technology demands constant innovation in PCB design and manufacturing processes. However, upgrading technology requires substantial financial investment and training for engineering teams. This challenge is multifaceted, as companies must balance the need for cutting-edge capabilities with budget constraints and workforce readiness. Additionally, adhering to the latest industry standards for quality and reliability in the production of PCBs can strain resources, particularly for smaller firms.

Lastly, competition in the PCB market presents a significant hurdle. With an increasing number of players entering the field, maintaining a competitive edge is crucial for sustaining market share. Fanuc must navigate not only pricing pressures but also differentiation through innovation and service quality. This competitive landscape can lead to pricing wars, which may compromise the quality of production as companies attempt to maintain profitability. Therefore, it is essential for manufacturers in the Fanuc PCB sector to strategize effectively, leveraging technological advancements and optimizing supply chains to mitigate these challenges in a highly dynamic environment.

Future Trends in Fanuc PCB Technology

The evolution of Fanuc PCB technology is characterized by ongoing research and innovations that promise to adapt to the growing demands of various industries. As the automation landscape continues to expand, Fanuc is at the forefront, integrating cutting-edge advancements to enhance the performance and reliability of its printed circuit boards (PCBs).

One significant trend is the increasing incorporation of artificial intelligence (AI) and machine learning algorithms into Fanuc PCB systems. By weaving these advanced technologies into PCB design and production processes, Fanuc aims to optimize operational efficiencies, minimize downtime, and enhance predictive maintenance capabilities. This integration holds the potential to transform manufacturing by allowing systems to adapt in real-time based on performance data collected from machinery.

Furthermore, ongoing innovations in materials science are expected to influence Fanuc PCB manufacturing. The development of high-performance materials that offer enhanced thermal and electrical properties will likely lead to more efficient and durable circuit boards. These advanced materials not only improve the PCB’s functionality but also support the miniaturization of electronic devices, thus aligning with the industry’s demand for compact and power-efficient solutions.

Additionally, the push towards sustainability is prompting Fanuc to explore environmentally friendly practices in PCB production. This includes the potential for utilizing recycled materials and reducing waste through smarter design methodologies. As environmental regulations tighten, adopting sustainable practices in PCB technology will not only ensure compliance but may also provide a competitive edge in the market.

As we look ahead, Fanuc’s commitment to leveraging these trends emphasizes its potential to remain a pivotal player within the PCB landscape. The company continues to evaluate and adapt its technologies to meet the evolving needs of industries reliant on print circuit boards, ensuring its relevance in a rapidly shifting technological landscape.

Conclusion

In this comprehensive guide on Fanuc PCBs, we have explored the pivotal role these circuit boards play in modern manufacturing processes. Fanuc, a leader in automation technology, utilizes highly intricate PCBs that enhance the performance and reliability of their machinery. These printed circuit boards are integral not only for the functionality of robots and CNC machines but also for ensuring efficiency and precision in operations across various industrial applications.

We delved into the design and manufacturing processes of Fanuc PCBs, highlighting their robustness and adaptability, which are essential for meeting the diverse demands of industrial automation. Additionally, we discussed the technological advancements that have been incorporated into these boards, including better thermal management, miniaturization, and integration of advanced sensors. These innovations contribute to the overall effectiveness of fanuc systems, enabling them to function optimally in rigorous working environments.

Moreover, the importance of reliability cannot be overstated when it comes to Fanuc PCBs. High-quality components and meticulous assembly practices ensure that these boards withstand the test of time, reducing downtime and maintenance costs significantly. The impact of reliable PCBs on productivity reinforces the necessity of investing in top-tier automation technologies.

In conclusion, understanding the foundational aspects and significance of Fanuc PCBs equips stakeholders in the manufacturing sector with insights into their operation and potential to enhance efficiency. As industries continue to evolve with technological advancements, further exploration of Fanuc PCB’s applications and innovations will provide valuable insights into future trends in automation. Embracing these advancements is crucial for businesses aiming to remain competitive in an increasingly automated landscape.